Project Overview:

Accuracy and defect-free quality for steering armature parts must be ensured in the automobile industry. The inspection traditionally done manually is time-consuming, and it is incapable of detecting all types of defects. Therefore, the current challenge was to come out with an AI-based vision inspection system.

Problem Statement:

Manual inspection of steering armature parts is inefficient, prone to human error, and fails to detect all defects; hence, quality suffers along with increased costs. Accuracy and efficiency had to be improved through an automated AI-driven solution.

Solution Proposed:

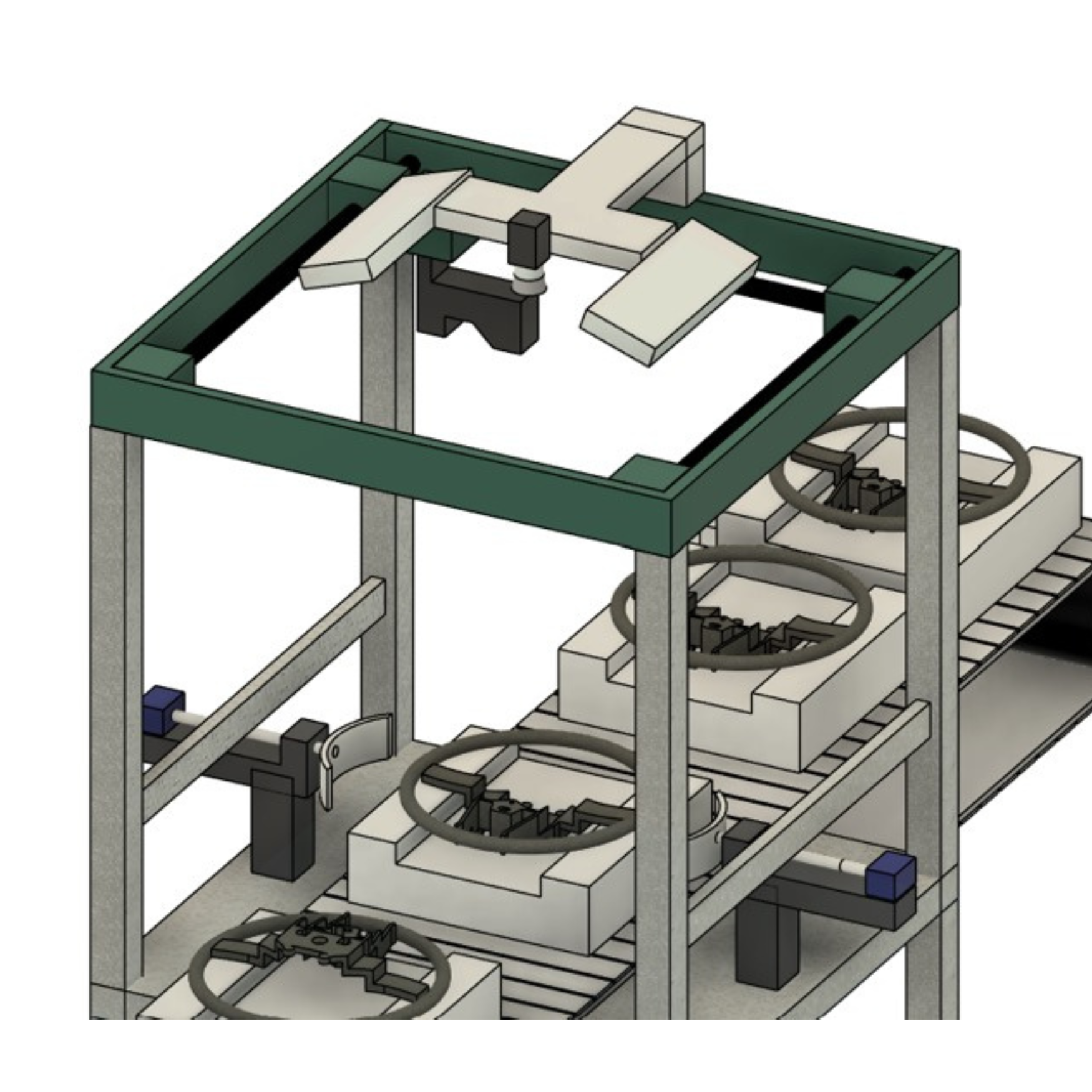

The solution required a customized AI-based vision inspection system for automatic scanning of steering armature parts. Triangulation lasers and high-resolution cameras, used by the system, can detect and classify defects in surfaces, identify dimensional inaccuracies, and run analytics in real-time.

Impact:

AI-based vision inspection system brought about critical improvements in the following parameters:

- Improved Accuracy: Accurate detection and classification of defects.

- Increased Efficiency: Reduced inspection time, with increased production cycles.

- Real-Time Data Analytics: Continuous monitoring and data analysis for improved quality assurance.

This advanced AI solution transformed the inspection process, ensuring superior quality control, reduced operational costs, and higher production efficiency.